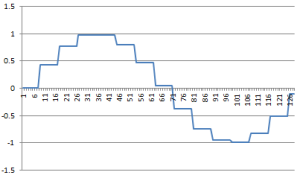

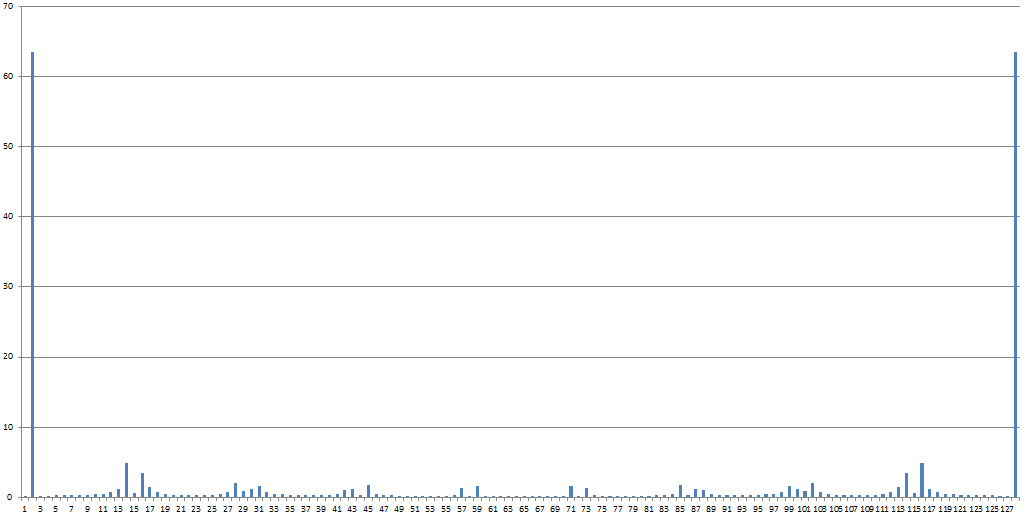

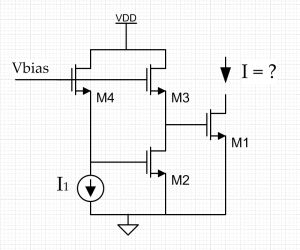

I needed some graphics illustrating the frequency spurs of the output of a DAC when converting a sine wave. The calculations of the spur frequencies is a function of the oversampling of the sinusoid and is trivial. But, I needed graphics. I thought about just drawing them in MSVisio but then decided that it would be fun to let Excel do the work for me.

So, I wrote a Visual Basic routine in Excel that first generated a sampled-data sinusoid, then calculated the FFT of that waveform and plots both the waveform and the FFT. The parametric inputs for the calculations are the number of data points (must be power of 2), and the over sample ratio. Again pretty simple stuff.

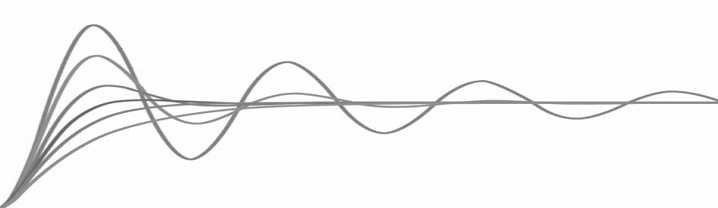

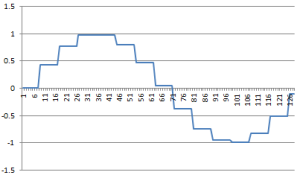

Here is an example output of a sampled sinusoid:

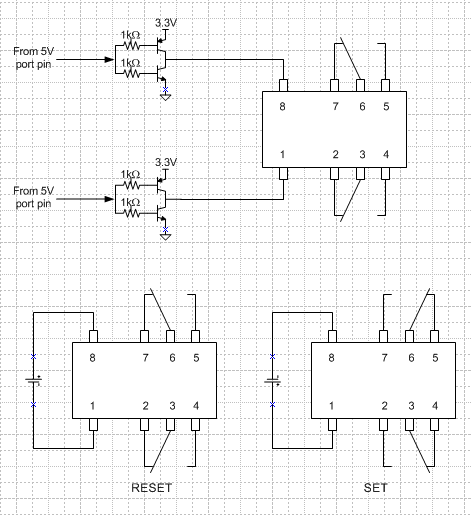

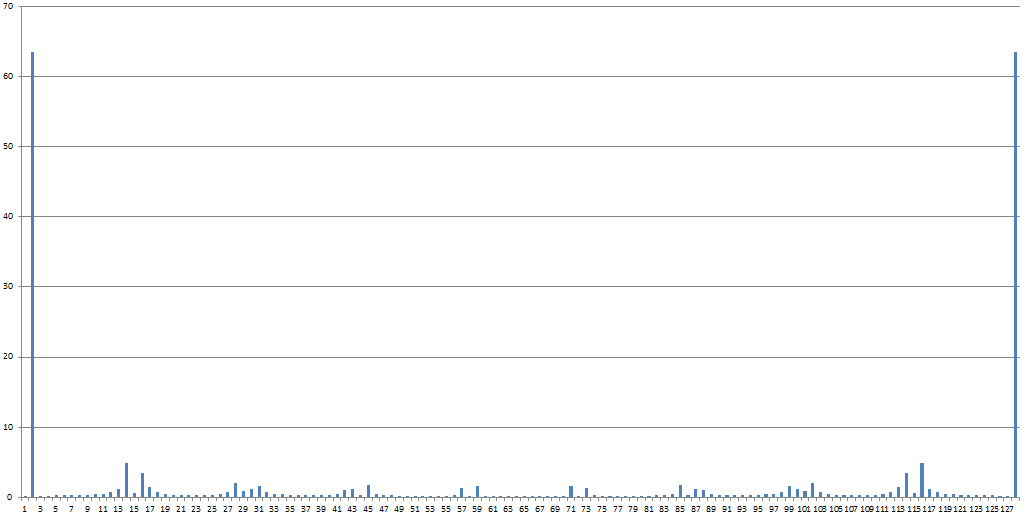

Here is the FFT output:

Here is the VB code to do this:

Sub FFTDAC()

Application.Calculation = xlCalculationAutomatic

Application.EnableEvents = True

Columns(“C:C”).Select

Selection.ClearContents

Pi = 3.1415926

Range(“H1”).Offset(0, 0).Select

samples = Selection.Offset(0, 0).Value

OSR = Selection.Offset(1, 0).Value

inc = samples / OSR

Range(“A1”).Offset(0, 0).Select

For i = 1 To samples

arg = i – i Mod inc

arg = arg * 2 * Pi / samples

Value = Sin(arg)

Selection.Offset(0, 0).Value = Value

Selection.Offset(1, 0).Select

Next i

Range(“D1”).Offset(0, 0).Select

For i = 1 To samples

cellname = “C” & i

fcn = “=ImAbs(” + cellname + “)”

Selection.Offset(0, 0).Value = fcn

Selection.Offset(1, 0).Select

Next i

Application.Run “ATPVBAEN.XLAM!Fourier”, ActiveSheet.Range(“$A$1:$A$128”), _

ActiveSheet.Range(“$C$1”), False, False

End Sub

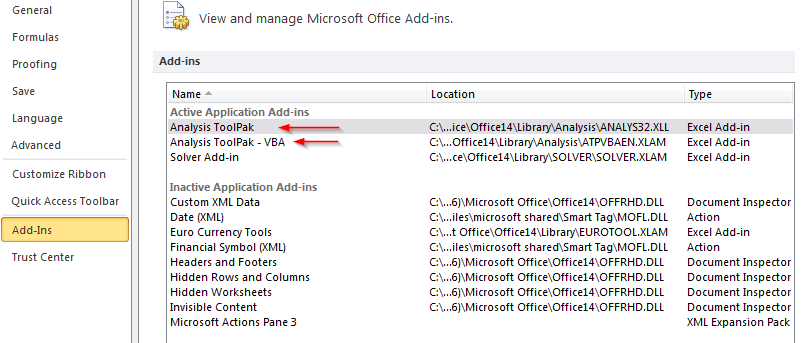

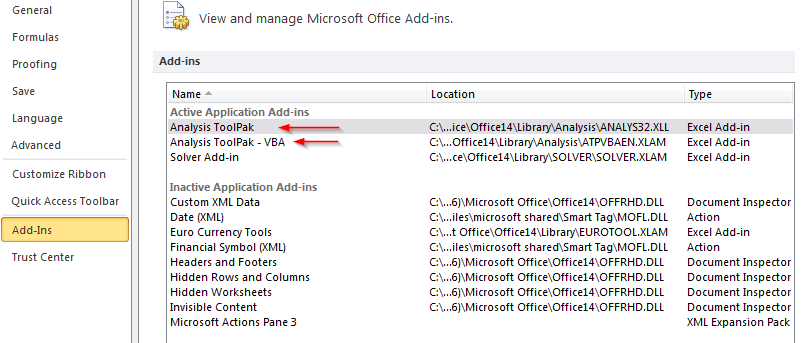

In order for this macro to work, you have to install/enable the Analysis ToolPak and Analysis ToolPak VBA